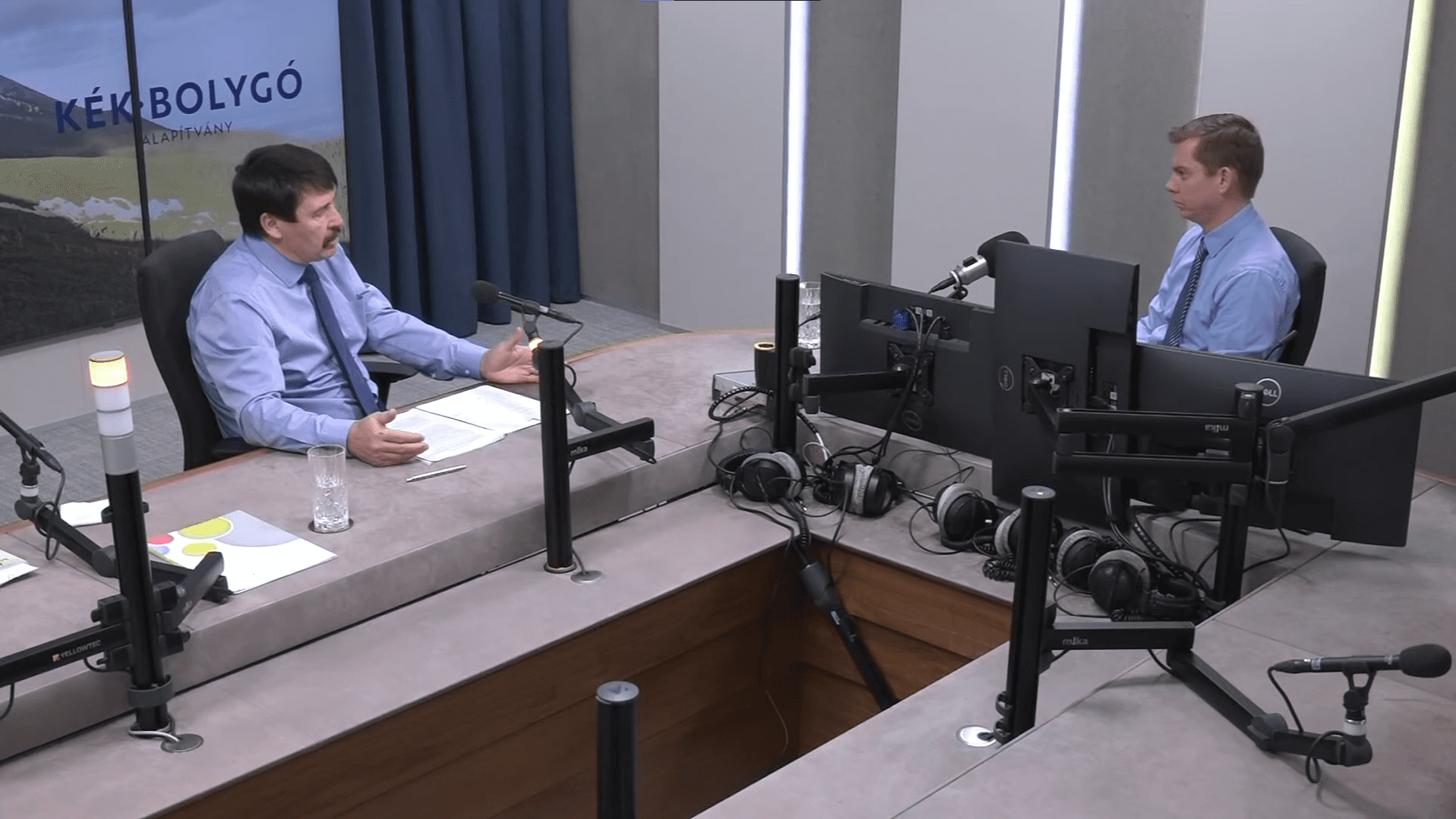

Former President of Hungary János Áder engaged in a discussion about battery production, its scientific background, environmental impact, and safe operation with chemist Róbert Kun in the latest episode of the podcast Blue Planet, released on Monday.

Áder, chairman of the Blue Planet Climate Protection Foundation, emphasized the significant scientific and economic foundations behind battery development. He recalled that in 1991, the first modern lithium-ion battery was introduced, for which three scientists were awarded the Nobel Prize in Chemistry in 2019. Róbert Kun, Research Group Leader at the Research Centre for Natural Sciences stated that batteries, as tools for energy storage, are key components of future energy systems. He cited examples such as providing power for mobile phones, mobile applications, laptops, and electric cars.

Áder noted that in Europe alone, 10 to 12 million cars are produced annually, and from 2035 onwards, only electric cars will roll off the assembly lines. This means that in Europe,

10 to 12 million batteries will be needed annually for car production.

Kun emphasized that with the increasing capacity of renewable energy sources such as solar and wind power plants, there will be an increasing need for energy storage systems. The researcher also pointed out that with the current technology, batteries are not suitable for seasonal storage. ‘A battery does not work like a pantry, where surplus energy produced in the summer can be taken out in winter,’ he explained. Currently, the storage duration is 6–12 hours, meaning that solar energy generated during the day can be used in the evening or possibly the next morning. Over the past decades, the efficiency and storage capacity of lithium-ion batteries have increased two and a half times. Kun illustrated the difference between traditional and modern lithium-ion batteries with a car analogy, likening lithium-ion devices to Formula 1 cars. Lithium-ion batteries are considered state-of-the-art technology with no current competitors, Kun highlighted. He noted that while there are other research directions, this is the one that has proven successful in technical and economic terms and is commercially available.

Energiatárolás jelene és jövője

Mobilalkalmazások, elektromos autó, laptop, valamint a megújuló energiaforrások tárolása. Egy dolog mindenképpen összeköti őket: az akkumulátorok. A Természettudományi Kutatóközpont Anyag- és Környezetkémiai Intézet Szilárdtest Energiatárolók Kutatócsoportjának vezetője szerint ezek kulcskomponensei a jövő energetikai rendszereinek. Ha bővítjük a nap- és szélenergiai hálózatot vagy ha az Európai Unióban 2035-től csak elektromos autók kerülhetnek piacra, akkor az akkumulátorok megkerülhetetlenek.

Áder summarized that what works in the laboratory may not necessarily be feasible in a car. Kun explained that the limitations of battery production lie in the restricted availability of raw materials and the capacity of refineries processing them. ‘Far Eastern, Asian companies dominate this area, with refining capacities significantly larger than those in Europe,’ he said. Consequently, Europe exposes itself to a dependency on mineral raw materials after fossil fuels. Áder emphasized that the United States provides significant, 35–50 per cent state support for battery production. These subsidies help them remain competitive and meet the growing demand from the American market.

Regarding battery recycling, Kun stated that production, operation, and recycling should be managed as a circular economy, and the necessary technological solutions exist. ‘If technical and safety regulations are followed,

it is possible to minimize environmental impact during battery production and recycling,’

the researcher said. However, he also pointed out that all chemical production, from paper manufacturing to drug production, carries its own environmental risks. He also highlighted that production takes place in a closed system, and the main elements of production technology are the same everywhere, whether it’s a factory in Sweden, Germany, Hungary, or the Far East.

Kun also mentioned that there are numerous research projects underway in battery development, including the optimization of zinc-ion and sodium-ion batteries.

Related articles:

Sources: Hungarian Conservative/Blue Planet/MTI